Maintenance - coronahandpiece.com - handpiece repair handpiece maintenance sharping tipping service

Main menu:

- Home

- Repair Services

- Products

- Sharpining/Retip

- Shipping

- Maintenance

- Contact

- Training

Maintenance

The major causes of handpiece failure are:

Sterilization

Lack of lubrication or proper lubrication

Being dropped

Ran with bent bur or no bur at all

Excessive air pressureLack of proper lubrication

Handpiece maintenance is the key to survivability. By properly cleaning and lubricating your handpiece before sterilization you insure that it will have a long life and run at its best

Running your handpiece at the Manufacturer’s suggested air pressure is very important. Higher air pressures will make your handpiece run faster but will cause premature bearing retainer wear.

Sterilization cannot be avoided and must be done in accordance with ADA/FDA regulations. Most Manufacturers recommend using an Autoclave or Chemiclave.

Dry heat and cold sterilizing are generally not recommended.

By using a quality lubricant/cleaner and following the procedures below you should see longer handpiece life.

Handpiece Cleaning & Lubrication Procedures

1. Clean exterior of handpiece using isopropyl alcohol and a towel

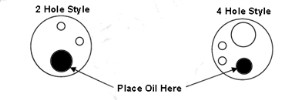

2. Spray or apply several drops of lubrication/cleaner into chuck tube

3. Spray or apply 1 to 2 drops of lubricant/cleaner into chuck area

4. Install straight bur into chuck. Ensure that bur is secure.

5. Rotate bur between thumb and index finger to help loosen debris particles lodged in turbine

6. Attach handpiece to air supply (purge units in sterilization area work best) point bur away from yourself and into clean white towel held in your opposite hand. Depress rheostat for approximately 30 seconds or until all lubricant/cleaner is expelled. The Expelled lubricant should be the same color as the contents in the lubricant bottle/can. Ensure that all lubricant is expelled.

7. Wipe away all lubricant/debris from exterior of handpiece.

8. Remove bur from handpiece.

9. Sterilize according to manufacturer’s instructions. Allow sterilizer to complete its cycle. Never cool handpiece by running cold water over it.

10. Re-

11. Wipe away all excess lubricant from handpiece exterior.

12. The handpiece is now ready to be used........ Click here for office copy

|

|

|

|

Scaler |

40- |

Slowspeed |

45- |

Note Handpiece air pressure should be checked at the handpiece

*Refer to your manufacturer’s handbook for exact settings.*